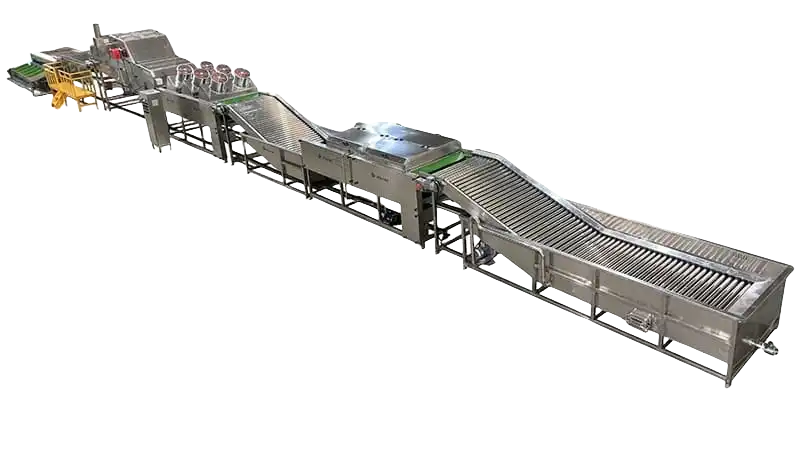

At YaXingFa, we pride ourselves on being a trusted manufacturer of high-quality fruit and vegetable processing machinery. Our commitment to excellence in quality, hygiene, and efficiency has enabled us to support a wide range of businesses in the food processing industry, ensuring they meet their production goals while maintaining stringent standards.

As a responsible manufacturer, we prioritize hygiene and quality from the very start of the design and production process. Every piece of machinery we create adheres to rigorous standards, ensuring reliability, safety, and top-tier performance.

At YaXingFa, we aim to deliver world-class fruit and vegetable processing equipment tailored to your business needs. Whether you’re looking for single machines or complete processing lines, our goal is to help you optimize production and achieve excellence in every aspect of your operation.

Partner with us and experience the difference in quality, innovation, and service. Let’s grow your business together with our advanced processing solutions!

At YaXingFa, we prioritize productivity, quality, and cost-effectiveness in every piece of fruit and vegetable processing equipment we produce. Our cutting-edge machinery is engineered to deliver exceptional operational value, helping your business achieve superior results while optimizing resources.

At YaXingFa, we understand the importance of meeting deadlines. Our streamlined manufacturing processes ensure that your equipment is delivered quickly, allowing you to start operations sooner and gain a competitive edge in the market.

Fruit processing plays a crucial role in preserving the taste and nutrition of fruits while enhancing their storability and transport convenience. Fresh fruits, although rich in nutrients, have a soft texture and high water content, making them highly perishable due to microorganisms and environmental factors. Advanced fruit processing techniques maximize the utilization of fruit resources and help balance market supply. Below are five commonly used fruit processing methods and their industrial significance.

Drying involves eliminating water from fruits through heating or other methods, effectively reducing water content and activity to inhibit microbial growth and prolong shelf life.

Natural Drying: Utilizes sunlight and air but depends heavily on weather conditions. Artificial Drying: Uses controlled environments such as hot air ovens or freeze-drying chambers, making it more efficient for industrial applications.

Extended storage time and reduced weight for easier transportation.

Process: Juicing extracts the natural liquid (cell sap) from fruits, providing a refreshing and nutritious product. Types of Juices: Transparent Juices: Apple, grape. Cloudy Juices: Orange, mango. Variants: Concentrated Juice: Has 3-6 times the concentration of original juice, with 40%-65% soluble solids, requiring dilution before consumption. Juice Powder: A further concentrated form with only 1%-3% water content, ideal for long-term storage. Applications: Bottled juices, concentrates, and powders.

Subscribe to our newsletter to stay updated on the latest food processing machines.

At YaXingFa, Our professional engineer will give you support in food processing machine. Contact us now and tell us your requirement. Our engineer will give you reply in 24 hours.

YaXingFa Copyright © 2025. All rights reserved.

Send us a quotation now and we will contact you in 24 hours.