For manufacturers eyeing the lucrative plant-based market, a critical question arises: can a standard beverage production line handle the job, or is a specialized line required? While a universal line offers a foundation, the unique physicochemical properties of plant-based ingredients demand specific engineering solutions.

This article provides a clear, data-driven comparison to guide your investment decision, highlighting the key differences in process, equipment, and performance.

Executive Summary: Core Differences at a Glance

| Feature | Standard Beverage Production Line | Specialized Plant-Based Beverage Line |

|---|---|---|

| Primary Purpose | Versatile production of clear liquids, juices, RTD teas, carbonated soft drinks. | Dedicated to processing suspensions & emulsions from nuts, grains, legumes. |

| Key Challenge | Dissolving ingredients, pasteurization, carbonation. | Particle size reduction, emulsion stability, starch management, off-flavor control. |

| Typical Yield | ~98-99% (minimal waste) | 85-95% (Highly dependent on grinding efficiency) |

| Final Product Stability | Physically stable (no suspended solids) | An engineered, metastable emulsion requiring homogenization. |

| Flexibility | High across various aqueous-based drinks. | High within plant-based category; lower for clear beverages. |

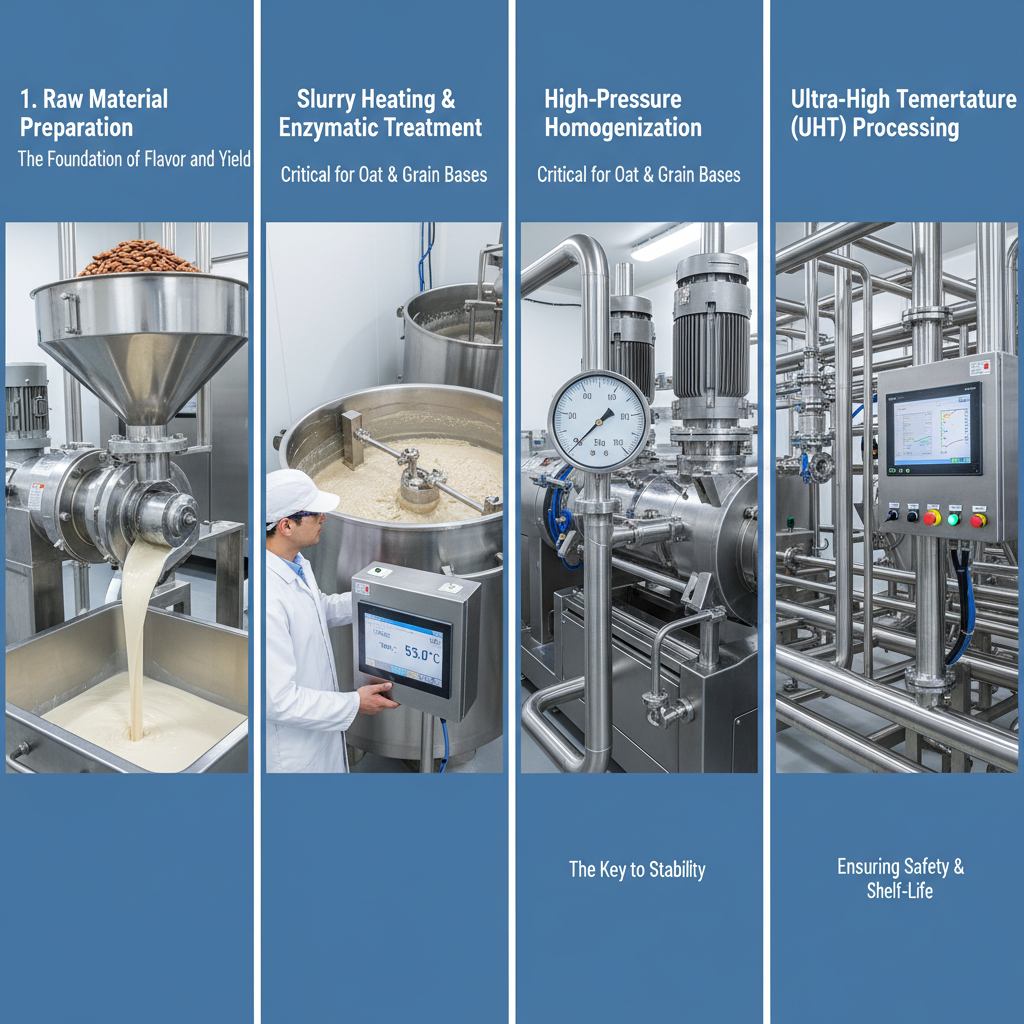

Detailed Technical Comparison by Process Stage

The following table breaks down the differences in each production stage, which are the primary drivers of cost and performance variation.

Technical Specification & Output Comparison

| Production Stage | Standard Beverage Line | Plant-Based Beverage Line | Impact on Product & Cost |

|---|---|---|---|

| 1. Raw Material Handling | Powder silos, liquid sugar tanks. | Soaking Tanks, raw material washing. | Added CapEx for PB: Soaking tanks (50,000-200,000 USD) are required to soften raw materials and improve yield. |

| 2. Grinding & Milling | High-shear mixer for powder dissolution. | High-Shear Colloid Mill/Rotor-Stator Mill. | Critical Difference: A standard mixer cannot break down plant cells. A colloid mill (75-200k USD) is essential to release proteins/oils and create a fine slurry, directly impacting yield and texture. |

| 3. Slurry Separation | Often not required. | Decanter Centrifuge or Separator. | Added CapEx for PB: A centrifuge (150-400k USD) removes insoluble fiber (okara), creating a smoother mouthfeel and increasing stability. |

| 4. Homogenization | Optional (for some dairy juices). | Mandatory. High-Pressure Homogenizer. | Critical Difference: Plant-based lines require higher pressure (150-250 Bar vs. 50-150 Bar). This is the single most important step to prevent oil separation and sedimentation, guaranteeing shelf-life. Cost: 100-300k USD. |

| 5. Thermal Processing | Pasteurization (75-95°C) or UHT (138-145°C). | UHT (138-145°C) is standard. Often uses Tubular design. | Key Consideration: Plant-based slurries are more viscous and prone to fouling. Tubular UHT systems (vs. plate) are preferred for better performance but come at a ~15-25% higher cost. |

| 6. Aseptic Filling | Standard for shelf-stable products. | Standard, but calibrated for viscosity. | Similar CapEx. The filler must handle slightly higher viscosity and particulates without clogging. |

Quantifying the Difference: Cost & Performance Analysis

1. Capital Expenditure (CapEx) Breakdown

A specialized plant-based line typically requires a 20-40% higher initial investment than a standard line of similar hourly output (e.g., 2,000 L/H), primarily due to the addition of three major components:

| Equipment | Approx. Cost Range (USD) | Necessity |

|---|---|---|

| Colloid Mill | $75,000 – $200,000 | Essential for PB |

| Decanter Centrifuge | $150,000 – $400,000 | Essential for most PB |

| High-Pressure Homogenizer | $100,000 – $300,000 | Essential for PB |

| Total Added CapEx | $325,000 – $900,000 |

2. Operational & Product Quality Metrics

The investment in specialized equipment directly translates to superior product quality and operational efficiency within the plant-based category.

| Metric | Standard Line (on PB drinks) | Specialized PB Line | Why it Matters |

|---|---|---|---|

| Particle Size (D90) | >50 microns | <20 microns | Grittiness vs. Creamy mouthfeel. |

| Emulsion Stability (7-day test) | Severe separation | No separation | Consumer rejection vs. product acceptance. |

| Extraction Yield (e.g., Almond) | ~75-80% | 88-95% | Directly impacts Cost of Goods Sold (COGS). |

| Shelf Life (Ambient) | Compromised risk | ≥12 months | Market reach and logistics. |

Conclusion: Which Line is Right for You?

The choice between adapting a standard line and investing in a specialized plant-based line hinges on your strategic goals.

- Consider a Standard Beverage Line if:

- You require flexibility to produce a wide range of non-plant-based drinks (juices, teas).

- You are producing a plant-based drink with pre-processed ingredients (e.g., ready-to-use almond flour or protein isolate), where grinding is not your bottleneck.

- Your budget is constrained, and you are willing to accept potential compromises in texture, stability, and yield.

- Invest in a Specialized Plant-Based Line if:

- You are serious about quality, brand reputation, and cost-effectiveness in the plant-based category.

- You process raw ingredients (whole almonds, oats, soybeans).

- You require maximum yield from expensive raw materials.

- You need guaranteed emulsion stability for a long shelf life.

In essence, while a standard line can be forced to produce a simple plant-based beverage, a Specialized Plant-Based Beverage Production Line is engineered to do it efficiently, consistently, and profitably. The higher initial investment is justified by superior product quality, higher yields, and reduced waste, ensuring long-term competitiveness in a demanding market.