The explosive growth of the plant-based beverage market presents a significant opportunity for beverage manufacturers. A critical question often arises: Can a standard Beverage Production Line be effectively used for Plant-Based Beverage Production?

The answer is a qualified yes. While a standard line provides an excellent foundation, producing high-quality, stable, and great-tasting plant-based beverages requires specific modifications and a deep understanding of the unique challenges posed by ingredients like oats, almonds, soy, and peas.

This guide walks you through the key stages of a standard line and outlines the necessary adaptations to successfully enter the plant-based market.

The Core Challenges of Plant-Based Ingredients

Unlike clear juices or sugar-based drinks, plant-based raw materials introduce specific complexities:

- Suspended Solids & Grittiness: Achieving a smooth, creamy mouthfeel requires breaking down hard fibers and cells.

- Emulsion Instability: Natural oils and proteins can separate, causing an unsightly layer on top.

- Starch Gelation & Viscosity: Ingredients like oats can turn into a thick gel during heating if not properly treated.

- Off-Flavors: Raw, “beany,” or grassy notes must be eliminated without overcooking.

- Low Extraction Yield: Inefficient grinding means valuable protein and fat are wasted in the pulp.

Adapting the Standard Beverage Line: A Stage-by-Stage Guide

Here’s how to transform a universal beverage line into a specialized plant-based beverage production line.

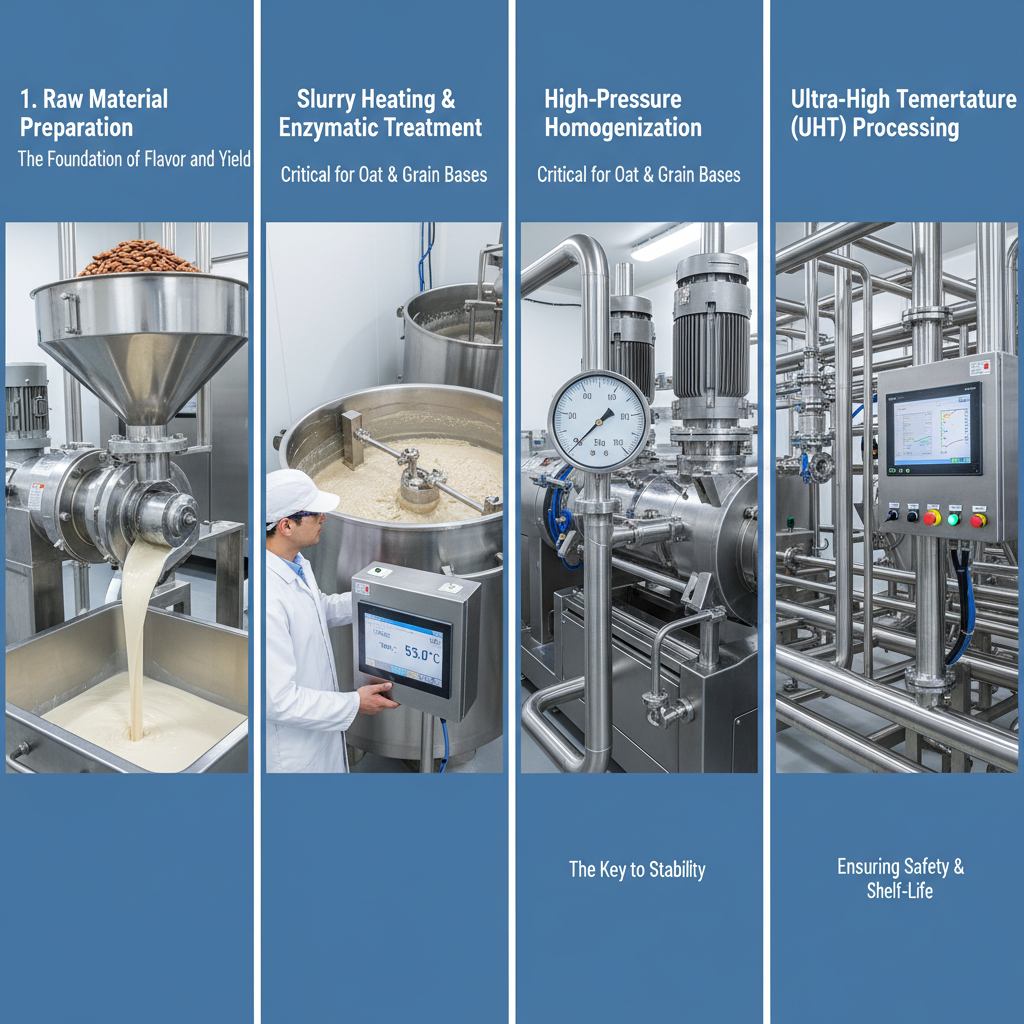

1. Raw Material Preparation: The Foundation of Flavor and Yield

A standard line often starts with simple powder or syrup mixing. For plant-based production, this must be augmented with a robust grinding and soaking station.

2. Slurry Heating & Enzymatic Treatment (Critical for Oat & Grain Bases)

This is a vital addition for many plant-based drinks. A standard mixing tank can be adapted into a temperature-controlled reaction vessel.

3. High-Pressure Homogenization: The Key to Stability

While some beverage lines may omit this, it is non-negotiable for plant-based products. This step must be placed before the final UHT processing.

4. Ultra-High Temperature (UHT) Processing: Ensuring Safety & Shelf-Life

A standard UHT system is capable, but must be configured for the higher viscosity and particulate content of plant-based slurries. Tubular designs are often preferred over plate-types to minimize fouling.

5. Aseptic Filling: Locking in Freshness

The principle is the same, but fillers must be calibrated for the specific viscosity and foaming characteristics of plant-based beverages.

Conclusion: A Strategic Path to Market

A standard Beverage Production Line is not just a starting point; it is a versatile platform that can be strategically adapted for high-volume Plant-Based Beverage Production. The key to success lies in recognizing the unique properties of plant-based ingredients and investing in the right modifications—primarily in ultra-fine grinding, high-pressure homogenization, and precise thermal processing.

For manufacturers looking to make this transition, the most effective approach is to partner with an equipment supplier who possesses proven expertise in both domains. Companies like YXF Food Machinery specialize in engineering such integrated solutions, providing the technical insight and customized machinery needed to retrofit your existing line or build a new one, ensuring your plant-based products meet the highest standards of quality, stability, and taste.