When investing in biscuit manufacturing equipment, customers often encounter several critical concerns that can influence their purchasing decisions. Addressing these pain points is essential for manufacturers to meet customer expectations and ensure satisfaction.

1. Product Quality and Consistency

Customers prioritize equipment that consistently produces high-quality biscuits with uniform shape, size, and texture. Inconsistencies can lead to product rejection and financial losses.

2. Machine Performance and Efficiency

The capability of the machine to operate at desired speeds and handle large production volumes without frequent breakdowns is crucial. Downtime can disrupt production schedules and increase operational costs.

3. Versatility and Customization

Manufacturers seek machines that can produce a variety of biscuit types and accommodate different recipes. The ability to customize shapes and sizes is also a significant consideration.

4. Ease of Operation and Maintenance

Complex machinery that requires extensive training can be a deterrent. Customers prefer user-friendly interfaces and machines that are easy to clean and maintain to minimize downtime and labor costs.

5. Cost Implications

The initial investment, along with ongoing operational and maintenance expenses, plays a pivotal role in the decision-making process. Customers seek cost-effective solutions that do not compromise on quality and performance.

6. After-Sales Support and Service

Reliable customer service, availability of spare parts, and prompt technical support are vital. Effective after-sales service ensures longevity and optimal performance of the machinery.

7. Compliance and Certification

Adherence to local and international food safety standards and possession of necessary certifications are mandatory for equipment used in food production.

8. Scalability

As businesses grow, the ability to upgrade or expand production lines without significant overhauls is advantageous.

YaXingFa’s Approach to Biscuit Manufacturing Equipment

Established in 2004, YaXingFa specializes in providing high-quality baking equipment tailored to meet diverse customer needs.

- Quality Assurance: YaXingFa’s machines are designed to deliver consistent product quality, ensuring uniformity in every batch.

- Performance Efficiency: The equipment is engineered for high performance, capable of handling substantial production volumes with minimal downtime.

- Versatility: YaXingFa offers machines capable of producing various biscuit types, accommodating different recipes and customization requirements.

- User-Friendly Design: Emphasis is placed on intuitive operation and easy maintenance, reducing the learning curve and maintenance efforts.

- Cost-Effectiveness: Providing competitive pricing without compromising on quality, YaXingFa ensures a favorable return on investment.

- Comprehensive Support: A dedicated after-sales service team offers prompt technical support and readily available spare parts.

- Compliance: YaXingFa’s equipment complies with relevant food safety standards and holds necessary certifications, ensuring safe and legal operation.

- Scalability: The machinery is designed with scalability in mind, allowing for easy upgrades to match business growth.

By addressing these critical customer concerns, YaXingFa positions itself as a reliable partner in the biscuit manufacturing industry, committed to delivering solutions that align with customer expectations and industry standards.

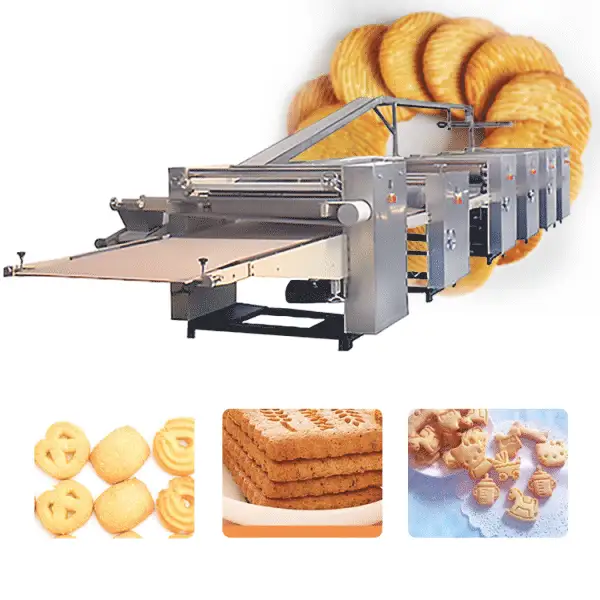

For a visual overview of YaXingFa’s biscuit manufacturing equipment, please refer to the following resources:

Image Gallery:

- Biscuit Production Line:

- Biscuit Making Machine:

These resources provide a comprehensive insight into the capabilities and features of YaXingFa’s biscuit manufacturing equipment.